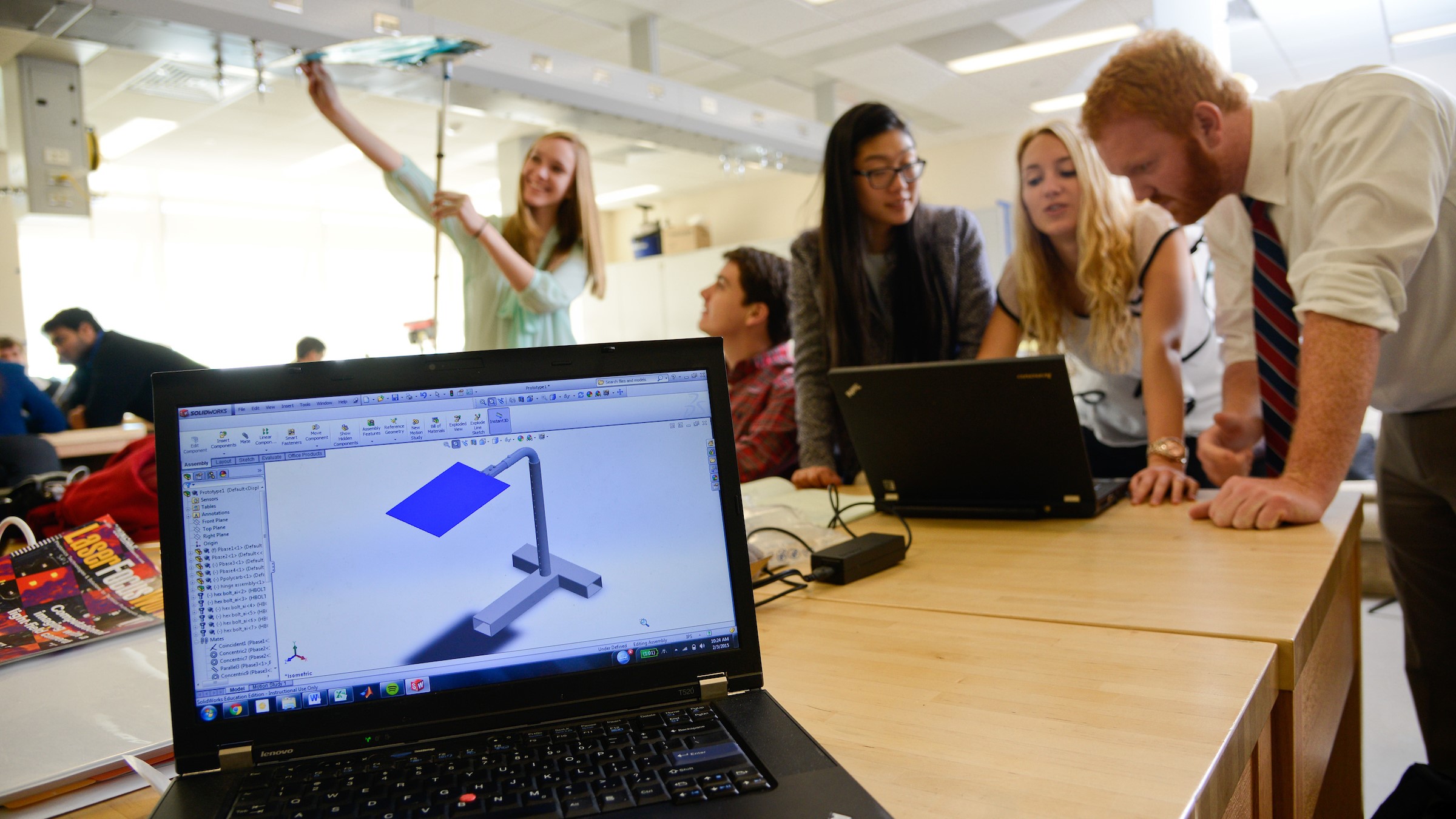

Excellence in Engineering

When you study at NC State Engineering Online, you are part of the NC State College of Engineering, a national leader. Students in our distance programs meet the same rigorous standards as those in the classroom.

Engineering Online Advisor

#11 in the U.S.

U.S. News & World Report rates us among the top online engineering programs.

19 programs

We have 19 online graduate degree and certificate programs.

40+ years

NC State has offered distance education in engineering since 1978.

STUDENT SERVICES

Looking for a way to expand your engineering team’s skill set? Engineering Online can help.